LVT stands for “Luxury Vinyl Tile” – a hard surface flooring product designed for use in both commercial and residential indoor applications. LVT is a vinyl plank or tile flooring that is available in a range of shapes, sizes, and visual looks. It can mimic an authentic-looking real wood or stone floor in your home without the drawbacks of natural products such as scratches on wood, heavy maintenance, and lack of waterproofing.

What is LVT Made Of?

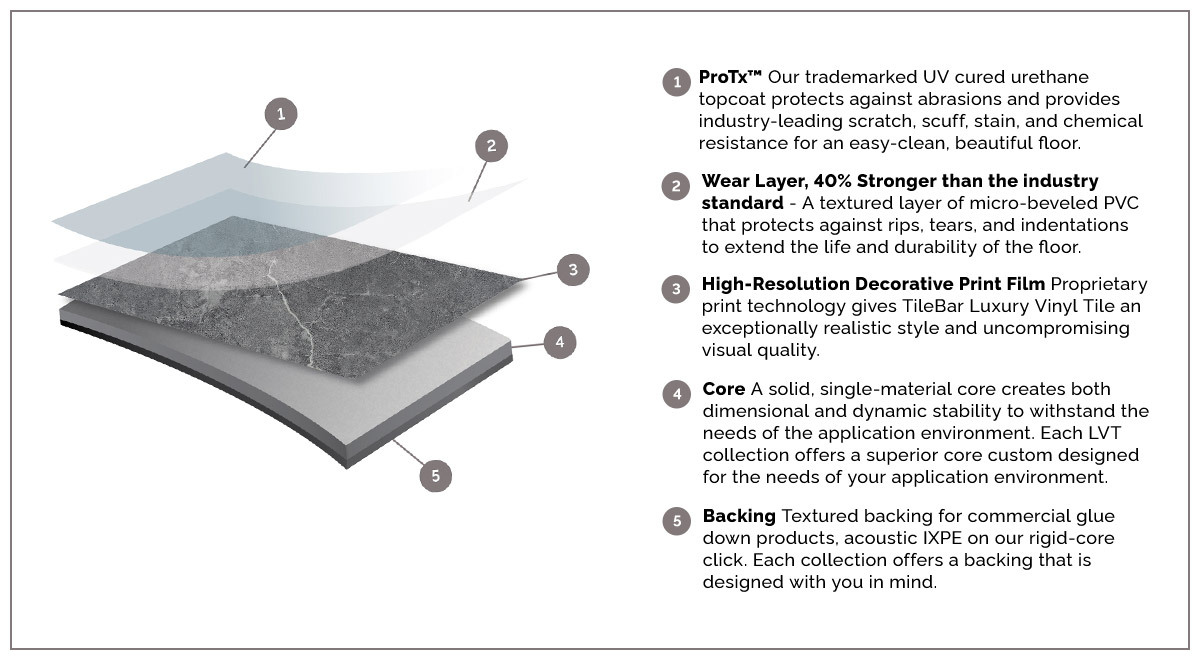

LVT is primarily made of polyvinyl chloride (PVC) and calcium carbonate (limestone). Luxury vinyl floors are made up of multiple layers that include a factory-applied urethane top-coat that protects against abrasions, scratches, scuffs, and chemicals, a protective vinyl layer that provides durability, a decorative PVC print film that provides the design and color, and a resilient vinyl backing.

Luxury vinyl flooring products come in different constructions that have been engineered based on different needs for different spaces. Some LVT floors come with an acoustic backing for additional comfort-under-foot, as well as sound-dampening properties. Others are specifically created for areas that need quick installation without any off-gassing from adhesives like hospitals and schools. There are even LVTs explicitly designed for sea-faring vessels like cruise ships!

Vinyl plank and tile flooring products are also being manufactured in a more sustainable way with more environmentally-friendly raw materials. For instance, phthalates have historically been used in PVC materials to make the product more flexible and soft, but have been linked to some health concerns. This has led many responsible manufacturers, like TileBar, to ban them from their manufacturing process. TileBar LVT products are also made from 100% virgin raw materials to ensure they remain free of metals such as lead, mercury, and tin, known instigators of health problems when people experience prolonged exposure.

How is LVT Installed?

There are multiple luxury vinyl flooring constructions that have been engineered to answer the different needs in both commercial and residential spaces. Innovations in the LVT product category have made the installation process easier for home-owners and installers.

- Glue Down: Also known as “dryback,” glue down is the most commonly used in commercial applications because of the heavy foot-traffic environments and heavy rolling loads. This installation method requires the use of an adhesive when installing. There have been many innovations with adhesives in the past 10 years beyond the traditional troweled-on application, including roll-on, peel, and stick, and spray adhesives.

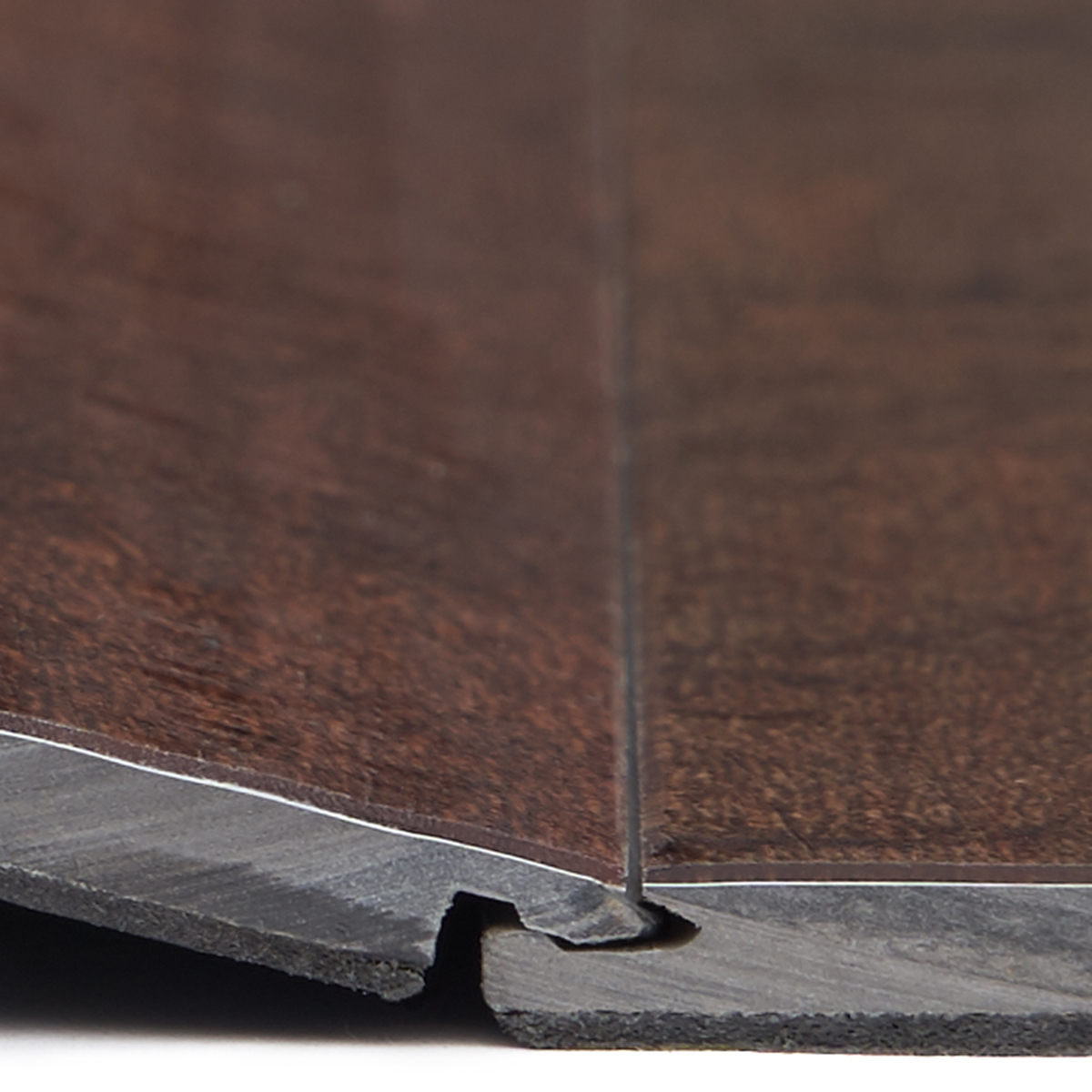

- Click: Unlike glue down, click does not require the use of adhesives, as the planks or tiles are installed by using the tongue and groove locking system on the edges of the product. This provides for a quicker and easier installation versus glue down/dry back. However, traditional click LVT has issues with subfloor irregularities and dimensional stability, so it has mostly been replaced by the improved rigid-core click product category.

- Rigid Core Click: This LVT has an installation process similar to the click LVT, but typically has a thicker and more rigid construction. The rigid core LVT construction provides better resistance to indentations, better dimensional stability, and added comfort-under-foot. There are 2 general rigid core categories: WPC (wood plastic core) and SPC (solid polymer core or stone plastic composite). WPC was the original rigid core construction introduced in the US market but experienced issues with product construction and dimensional stability. SPC flooring was introduced to fix the flaws that WPC flooring experienced, offering a more structurally stable and waterproof construction.

- Loose Lay: This LVT version is a thicker product construction versus glue down (typically 5.0mm). Most manufacturers promote loose lay LVT in smaller spaces with no rolling loads since minimal adhesive is required around the perimeter. The manufacturers recommend an adhesive be applied to loose lay LVT in a medium-sized room (width of the room larger than 20 feet) on the perimeter of the room, or even a grid of adhesive every 8 feet. In applications with heavy foot traffic or rolling loads, manufacturers recommend doing a full spread of adhesive with loose lay which turns it into a glue-down installation. The benefits of loose lay are a quicker installation process, acoustical benefits, use on sub-floors with high moisture content, installation over existing floors, and more comfort-under-foot.

Why Should I Use LVT?

LVT flooring solutions have become a popular choice for commercial and residential spaces for many reasons. LVT is more durable than many real wood floors, holding up to the daily wear and tear, and can be easier to maintain than a natural stone since it does not require any sealing or refinishing. LVT also does not have grout joints like ceramic, porcelain, and stone have to seal and maintain. LVT is waterproof, too, making it easier to clean and maintain compared to real wood or laminate flooring. Many also consider LVT warmer underfoot compared to real wood or stone.

LVT is a budget-friendly flooring solution thanks to an affordable up-front purchase cost and a low cost of maintenance over its lifetime, making it a great return on investment. Some LVT solutions are easy to install, saving time and money. Products like rigid core click can even be installed over existing hard surface products, eliminating the mess, time, and expense of tearing out an existing floor.

LVT can also better acoustics/sound dampening properties compared to real wood, laminate, stone, or ceramic tile. This can be especially useful if installing on an upper floor where footfalls can translate through the ceiling.

Which is Better: LVT or Laminate?

Both luxury vinyl flooring and laminate are durable and more affordable flooring solutions compared to hardwood, and can also require less maintenance. LVT is a waterproof and dimensionally stable flooring solution, compared to laminate. LVT products like rigid core click and loose lay also offer improved acoustical performance to laminate. Both LVT and laminate flooring options offer good stain resistance.

Rigid Core LVT construction has superior resistance to indentations versus laminate. For example, dropping a billiard ball on laminate will most likely create an indentation or crack the floor, Rigid Core LVT can withstand the drop without damage.

Can LVT Be Used in Bathrooms and Kitchens?

LVT is a great flooring solution for most indoor residential applications, including bathrooms and kitchens if you use a non-water-soluble adhesive. While the LVT itself is waterproof, it should never be used inside of a shower. In showers, you will need a solution that has more grip or grout lines to ensure that if a foot slips, it can catch the grout line or other non-skid surface so the person’s foot does not slide. A smaller tile with more grout lines, like a floor-rated mosaic, is a great option for this, such as the Meadowmere collections.

For residential kitchen areas, LVT has great chemical and stain resistance, though all spills should be cleaned and dried to prevent any potential hazards.

LVT can also be a great solution for commercial bathrooms. Just like residential bathrooms, LVT should not be used inside the shower and a non-water-soluble adhesive should be used. LVT should not be used in commercial kitchens as the amount of oil and grease that can end up on the floor, along with the required frequency of cleaning up the oil and grease can lead to hazards. A tile like the Fordham is better suited for commercial kitchens. LVT can be used outside of a commercial kitchen, but the use of walk-off mats is highly recommended.

How Should I Protect My LVT Floors From the Furniture Sitting on Top?

Place felt pads under the feet of the furniture so that scratches caused by tables and chairs being moved across the floor can be eliminated. Make sure to use desk chairs with resilient caster wheels to prevent damaging LVT floors.

What if I Scratch or Scuff an LVT Floor After Installation? What Can I Do to Repair the Floor?

Any floor can be scuffed by furniture or shoe soles rubbing on your floor. A simple solution is to use a tennis ball or cleaning eraser to lightly buff away the scuff mark. Small/light scratches can be fixed by applying a finish or vinyl floor sealer to the scratched or scuffed area.

If the damage to the LVT floor is more severe, like a gouge, cut, or dent, you can simply replace the damaged plank or tile. Most manufacturers recommend ordering an extra 5-10% of square footage for the project in case additional short pieces are needed to be cut. For more intricate design layouts, manufacturers recommend ordering more than 10% more material.

No floor is indestructible, but LVT is a very durable material that is designed to stand up to life’s daily wear and tear.

Popular Looks